Energy Audit At Kewpie Malaysia Sdn. Bhd

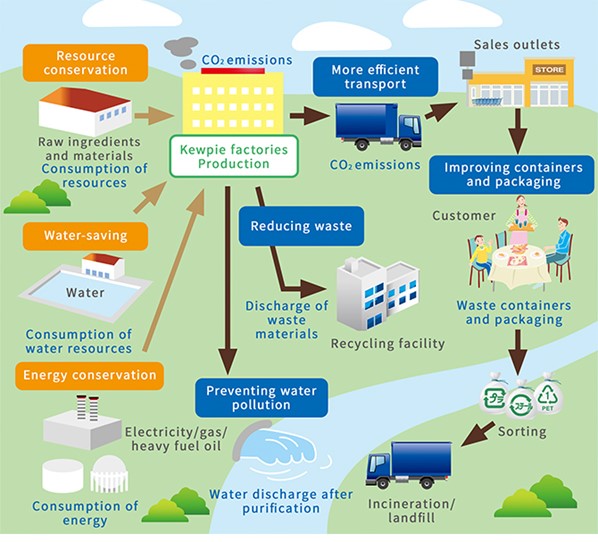

Energy audit at Kewpie Malaysia Sdn. Bhd lead by Dr. Mohd Yusof bin Taib from Faculty of Manufacturing and Mechatronic Engineering Technology (FTKPM). Services were provided to a local industry, to analyze adequate, secure and cost-effective energy supply, promote and encourage efficient utilization of energy and discourage wasteful usage of energi and to analyze and reduce the negative impacts of energy production, utilization and consumption on the environment.

This energy audit program is a part of an initiative supported by Energy Efficiency Projects Malaysia under the Eleventh Plan (RMK-12). The audit aimed to analyze and reduce energy consumption in the factory. This five-year project, running from 2021 to 2025, is open to various industrial sectors and is executed by the Ministry of Energy, Green Technology & Water (KeTTHA) and the Energy Commission.

The report emphasizes that all savings and cost estimates provided are for informational purposes only, and Techikara Engineering Sdn. Bhd. disclaims liability for any unmet savings measures or costs. The company has no financial interests in any recommended equipment or services.

KEWPIE Malaysia Sdn Bhd, based in Merlimau, Melaka, is a leading manufacturer of sauces, salad dressings, and egg-based food products, primarily using machinery from Japan. The facility produces around 7,033 metric tons annually, focusing on mayonnaise, dressings, spreads, and sauces through processes such as pasteurization, mixing, filling, and cartoning. The energy audit includes two scopes: compulsory (sustainable energy management, energy balances, and load profiling) and specific (focused on electrical motors, compressors, and steam generation). KEWPIE receives a three-phase 11 kV electricity supply from Tenaga National Berhad (TNB), resulting in total energy consumption of 2,018,629 kWh from October 2021 to October 2022, costing RM 942,437.76. The specific energy consumption (SEC) was calculated at 287 kWh/ton/year. A power logger revealed that the main switchboard (MSB) is fully utilized for various processes, including mixing and bottling, and supplies energy to the boiler, which runs on diesel fuel. The energy cost breakdown shows that electricity accounts for 63% and boiler fuel for 37% of total energy costs. Three Energy Saving Measures (ESMs) were identified: two no-cost measures and one low/medium cost measure. Implementing these measures could save approximately 558,586.29 kWh of energy (27.67% reduction), translating to RM 234,862.03 in cost savings and a reduction of 310.63 tons of CO2 emissions. The report also includes comparisons of current and expected energy consumption post-implementation of these measures.